![]()

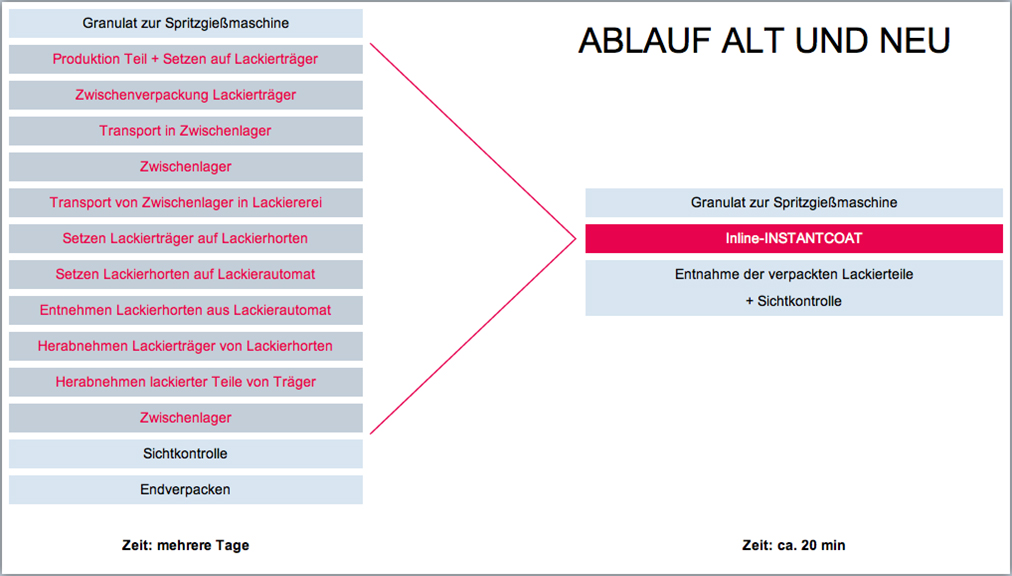

"By direct and fully automated linking of injection moulding, coating and final packaging with INSTANTCOAT® Plus we have reached the presently conceivable optimum in efficiency and product quality."

Dipl.-Ing. Michael Däbritz

Manager of VARIOPLAST®

- Material input

- Production scrap

- Personnel Costs

- Cycle Time

- Response time to problems

- Storage time of parts before coating

Critical aspects are improvement of part quality, process repeatability and flexibility:

- Regular coating layer thickness

- Improved surface appearance

- Improved coating adhesion (dirt-free parts)

- Part defects directly recognizable during process

- Shorter reaction time in case of malfunctions

- Process parameters repeatable and coordinated.

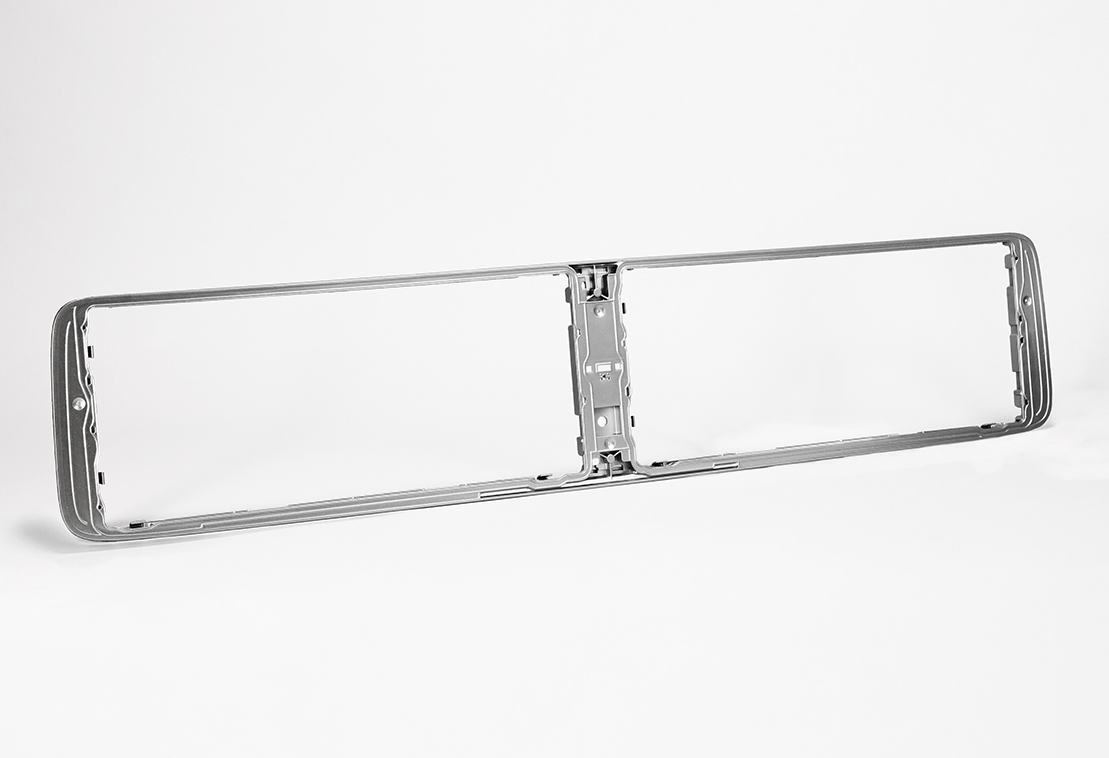

Mountingframe

2K-Injection Moulding + CO2 pre-cleaning + coating + dry + coating + dry

INSTANTCOAT®: 75% reduction of the ecological grey footprint

Source:

![]()

Download

High-tech injection molding

2K-Injection Moulding + Sheet Metal Overmolding + Insert Overmolding + US-Welding + Pad Printing + polishing + Drill

![]()

„The INLINE-metallization process INSTANTCHROME® by means of PVD, developed by VARIOPLAST®, is a perfect fit for our strategy of INHOUSE-process chains and has replaced galvanic chrome plating in our company.“

Dipl.-Ing. Michael Däbritz

Manager of VARIOPLAST®

-

The process chain of INSTANTCHROME®

1. Injection Moulding

2. Priming, UV-coating/drying

3. Chrome plating (PVD-Coating)

4. Topcoat (decorative protective coating) with solvent based and solvent free coatings, UV coating

5. Automated packaging of the coated products -

Advantages of INSTANTCHROME® versus galvanization process

● Fully automated process from injection moulding to ready-coated and packaged product

● Repeatable due to exactly adjustable parameters for coating and chrome plating

● Qualitative advantages due to constant process conditions

● Significantly lower scrap rate

● Direct part assessment during process

● No Hot Touch Effect

● Energy conservation

● Environmental compatibility (no hazardous waste)

● Cost savings -

Applications of INSTANTCHROME®

Decorative and functional coatings (matt and shiny)

-

Significant Advantages compared to galvanically chrome-plated parts

● Selective coating for fiber optics/reflector

● Various coating materials and polymers applicable

● Even snap-on hinges, clip closures, film hinges possible

● Ultrasonic welding, day & night design lasering feasible -

Hochschule Karlsruhe – Bachelor Thesis at Varioplast

Coating process of the PVC-Magnetron-Sputter process with optimization of the chrome coating by application of optimal design of experiments on the physical functionality of Magnetron Sputtering - optimal design and application of experiments (DoE) - Characteristics and Behaviour of Chrome during sputtering

-

Fulfilled Objectives

● no visible cracking

● best adherence of chrome on plastics

● optimization of UV-protective coating in accordance with quality standards of automobile manufacturers

● coating with paint (Primer/Topcoat)

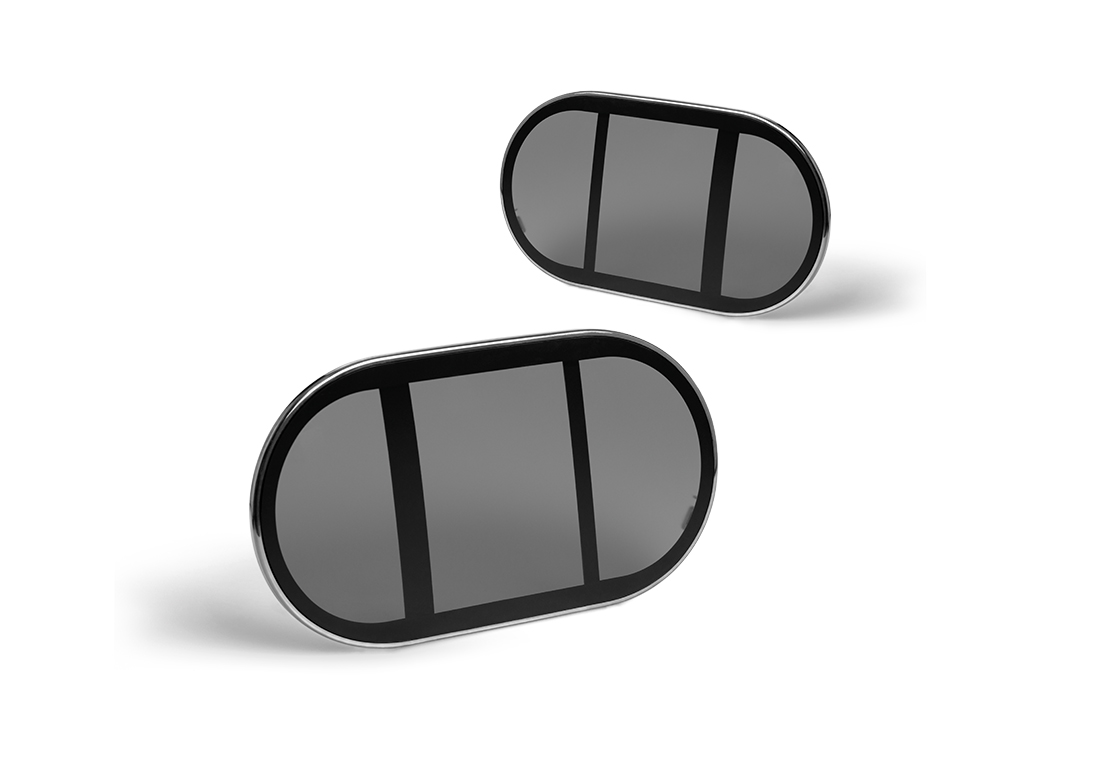

Black Panel Technology

2K-Injection Moulding + Variothermie + Pad Printing + PVD-Coating + coating + US-Welding + Laser cutting