Serial manufacturing

Everything at one location

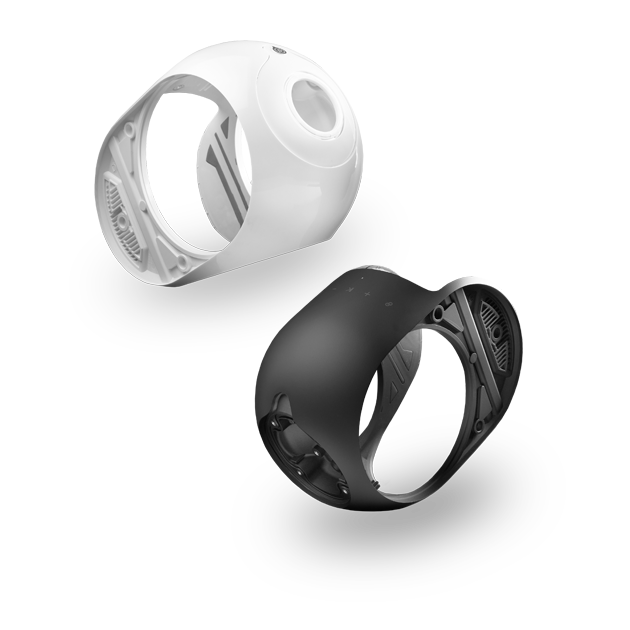

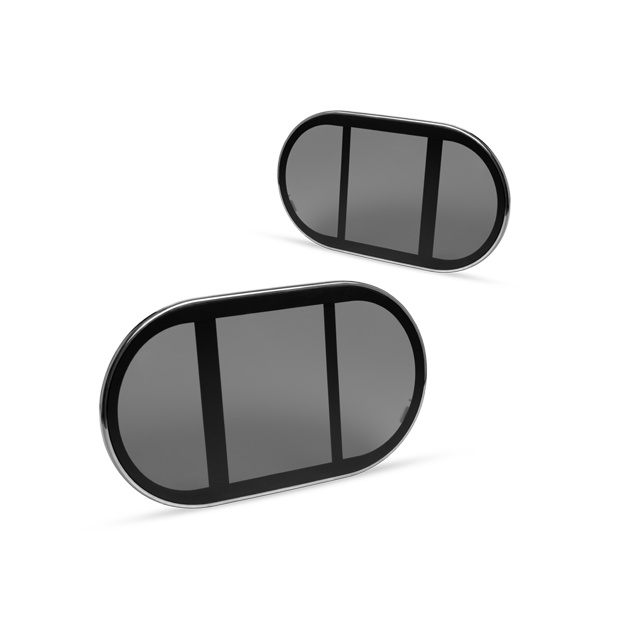

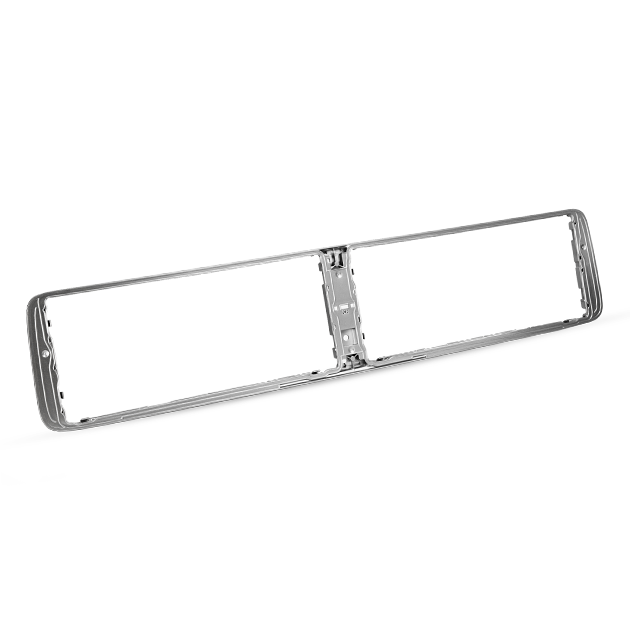

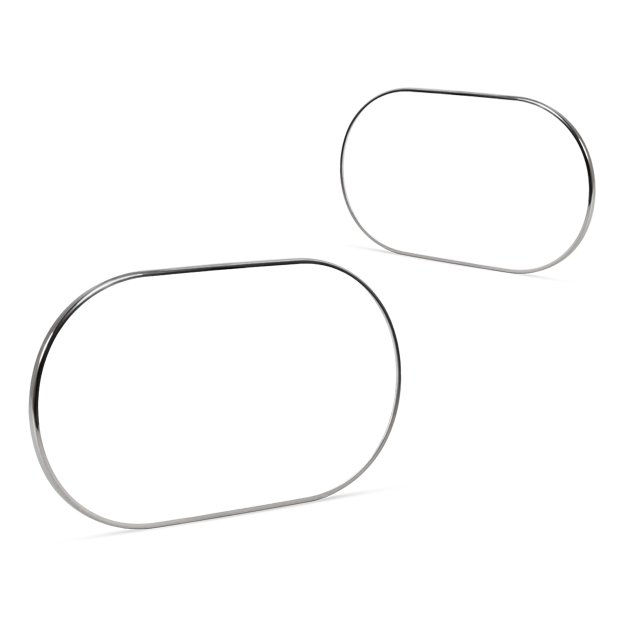

In addition to our core competence of plastic injection molding, you will find a wide range of other manufacturing competencies in the field of surface finishing and component assembly bundled under one roof. We achieve maximum efficiency and cost-effectiveness through automated networking of individual processes, customer-specific (product-specific) fully automated inline processes and exceptional solutions.

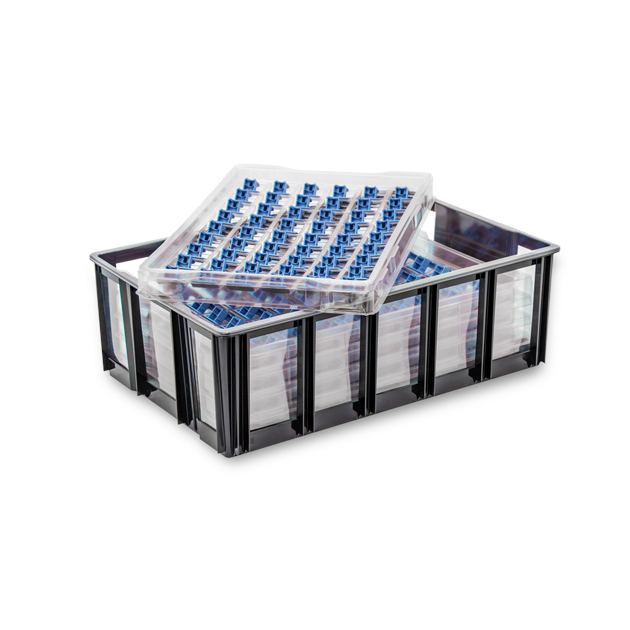

Our 3-shift operation based in Germany is certified to IATF 16949, DIN EN ISO 9001 and 14001. We are not just plastics processors and finishers, we are developers, designers and inventors. From toolmaking to customized packaging of the finished part, we are your expert partner for large and small quantities.

We supply well-known national and international customers from a wide range of industries and have received a positive response to our comprehensive and complementary services.

Because our environmental awareness has been an integral part of our company philosophy for over 50 years, it is reflected in various levels and technical environmentally friendly alternatives.